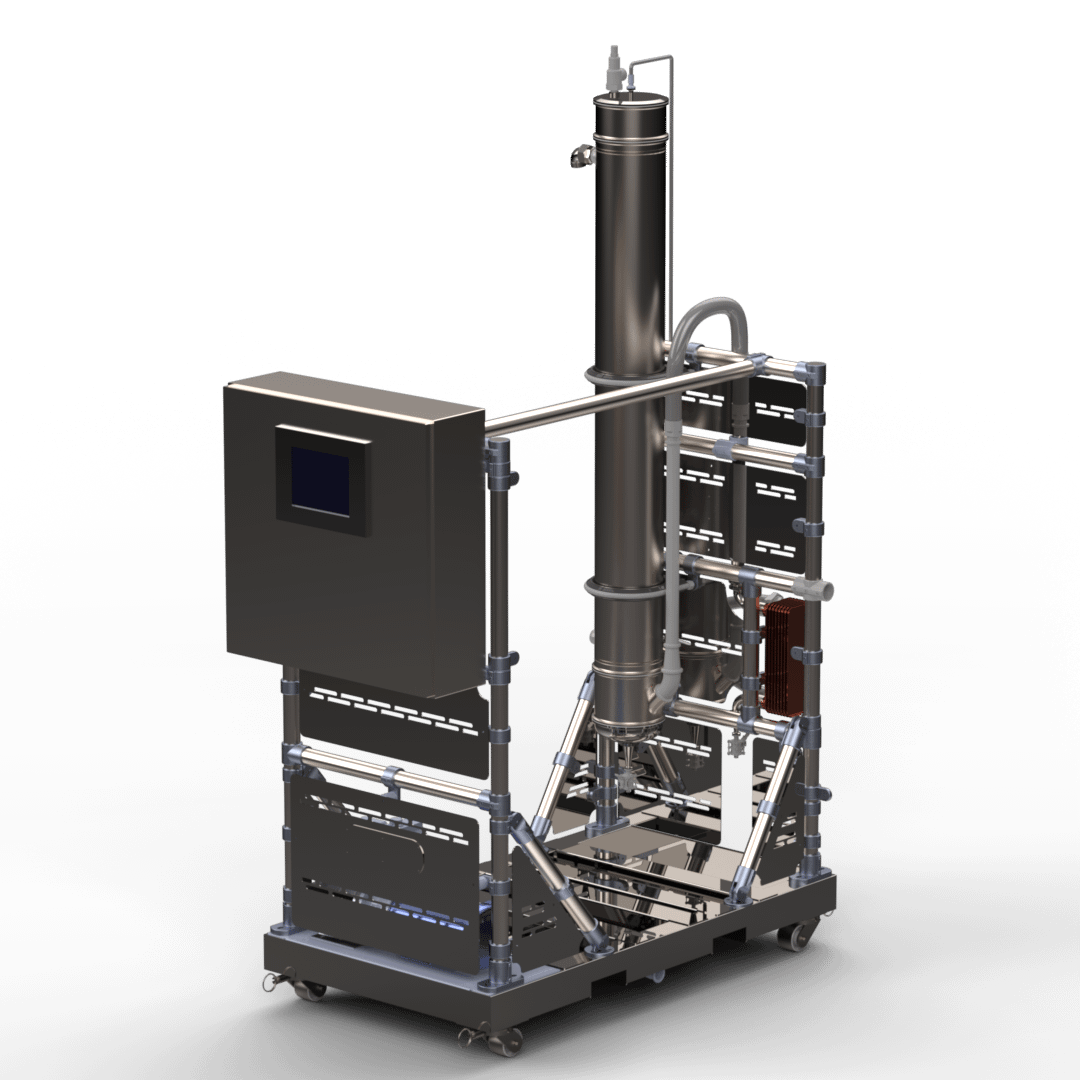

Falling Film Evaporator System

The Falling Film Evaporator, FFE, is modern solution to recover solvent from extraction solution with variation in flow capacities, easy one-man operational procedure and high rate of recovery, which makes unit more flexible to operate continuous oil production for long time without use of small rotary evaporators at lower production days.

Technical Specification Highlights

- Stainless Steel Vessels with Interior Polish

- Feed Flow Rate: 40-50 GPH

- 5ft x 3ft x 7ft High Footprint (Made to fit through a typical 36″ Door)

- Operational Temperature: 205 Deg. F

- Auxiliary Equipment Available:

- Electric Water Heater

- Hot Water Pump

- Water Cooling Tower

- Cool Water Pump

- 1.5″ Sanitary Tri-Clamp Fittings

- PLC with Touchscreen

- IOT with Datalogging and Remote Diagnostics

Why choose our Falling Film Evaporator System?

We’re not trying to oversell!

We know what you need in a Falling Film Evaporator. Although a traditional company that provides this equipment can provide them to the extraction market, typically they are selling you a vastly oversized piece of equipment engineered for another industry. Our equipment is specifically engineered for the extraction client.

Frequently asked Questions

Do I require a C1D2 Space for the Falling Film Evaporator?

That depends on your solvent of choice, but generally yes. We can recommend a selection of pre-built rooms if your require a new one for your installation.

Can the Verdara FFE be used for any Botanical?

YES! Our FFE System can be used effectively on a variety of botanical extract.

Is the Verdara FFE System Manufactured in the USA?

The Verdara FFE Skid is manufactured in Illinois, USA. The design is owned wholly by Verdara and currently not available through third parties on its own.

Do you have a full system with chilling, filtration, falling film, etc. available?

A full ethanol solvent extraction system can be procured through Luna Technologies of Portland, Oregon. The system, named Elara, is developed in partnership with Luna Technologies and manufactured by Verdara.